RATTMMOTOR YPMC-1000W 220V Servo Motor Kit with Servo Motor Driver, CNC Controller Kit for CNC Engraver Milling Machine/Robot (Without Brake)

-

Detail

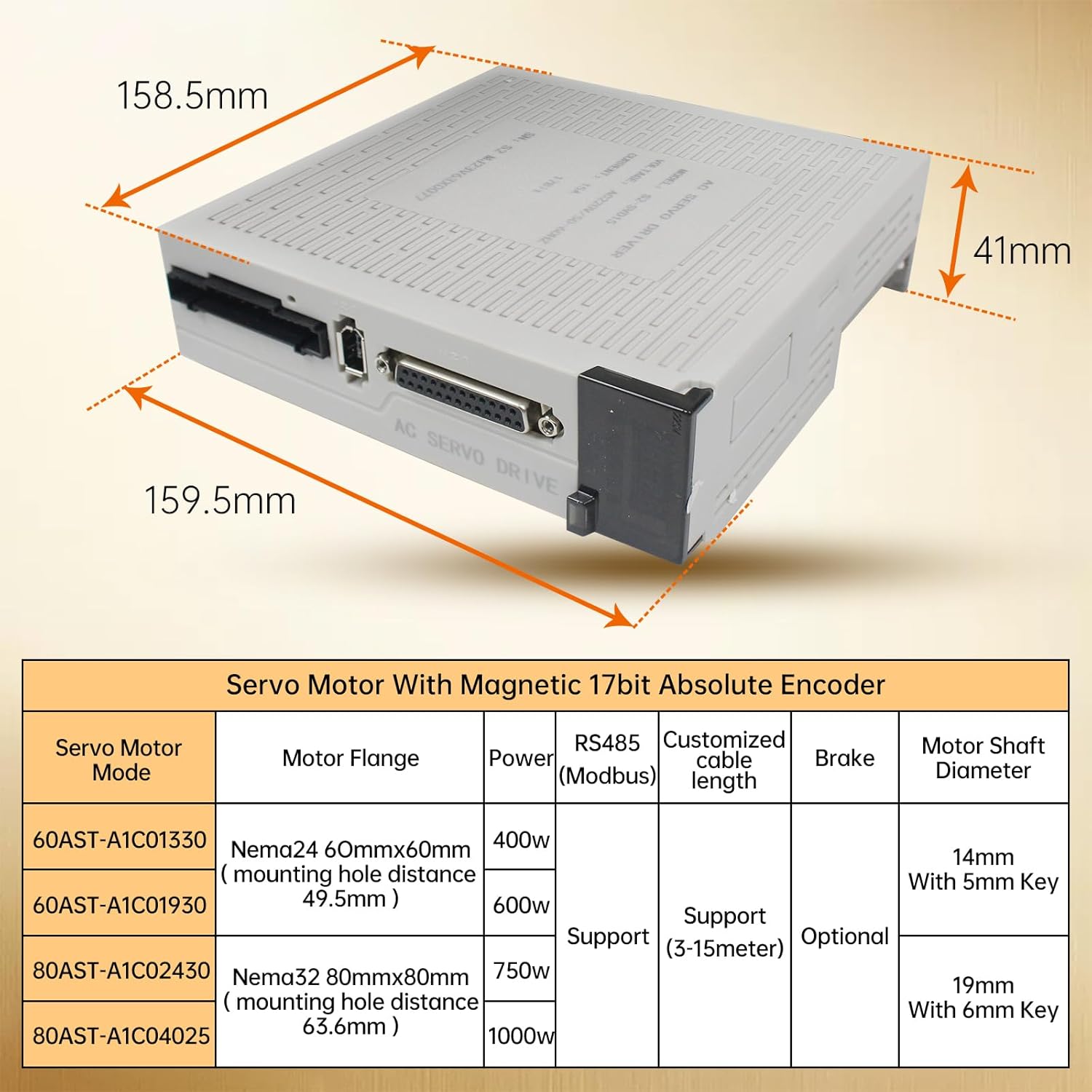

1 * A2M-80SV03230 Type 1000W AC Servo Motor without brake

1 * S2SVD20 Type Servo Drive

1 * DB25 hole plug and shell

1 * 3m Power cable with plug

1 * 3m Encoder cable with plug

1 * Pdf. user manual (If you have not received the user manual at Amazon Message Center from us,please message us)

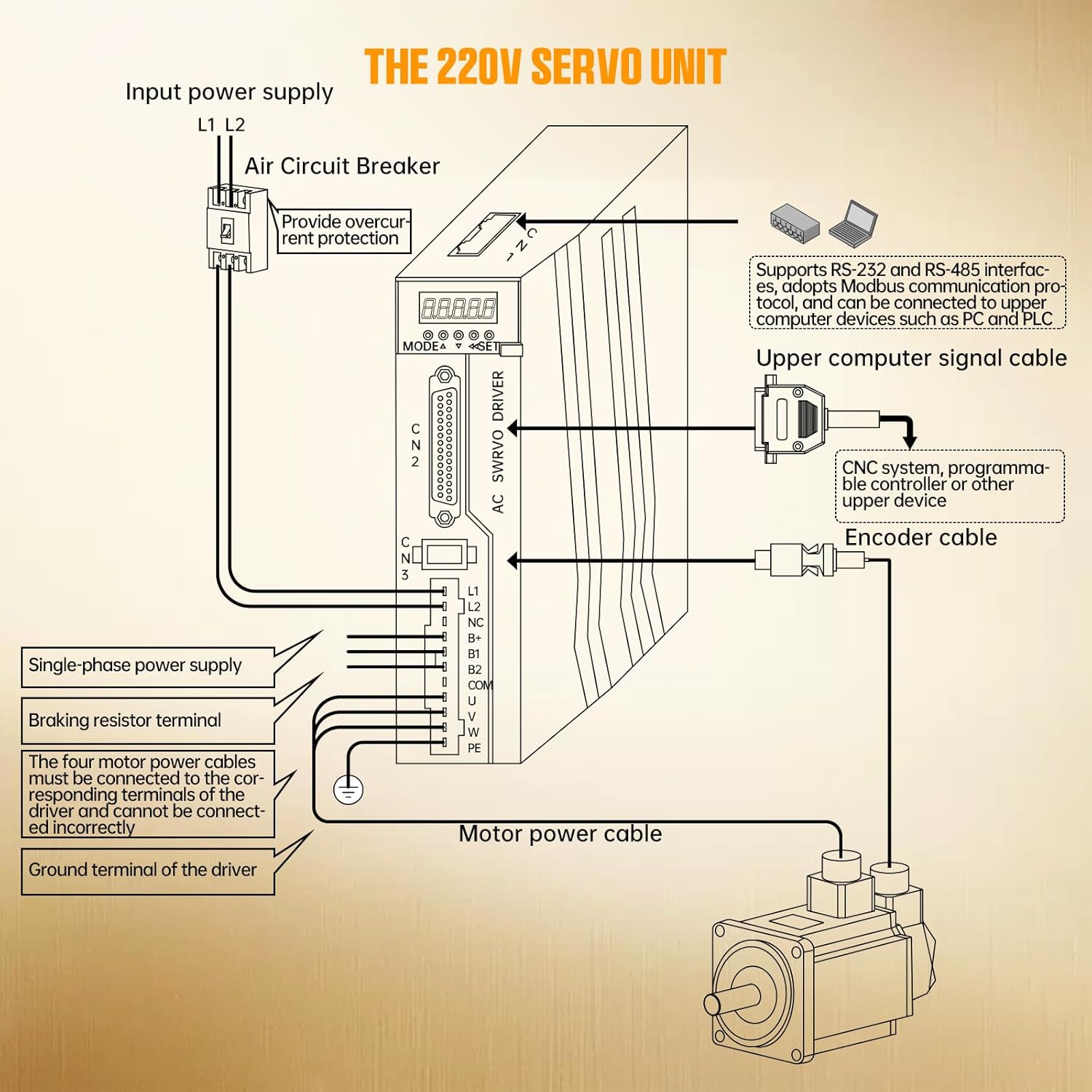

CN1 port:

- Support RS-232 and RA-485 interfaces, adopts Modbus communication protocol, and can be connected to upper computer devices such as PC and PLC.

CN2 port:

- Upper computer singal cable. Can be connected to CNC system, programmable controller or other upper device.

CN3 port:

- Encoder cable. Connected to servo motor.

L1 / L2:

- Input power supply.

B+ / B1 / B2:

- Braking resistor terminal.

U / V / W:

- Motor power cable. The four motor power cables must be connected to the correspoonding teiminals of the driver and cannot be connected incorrectly.

PE:

- Ground terminal ofthe driver.

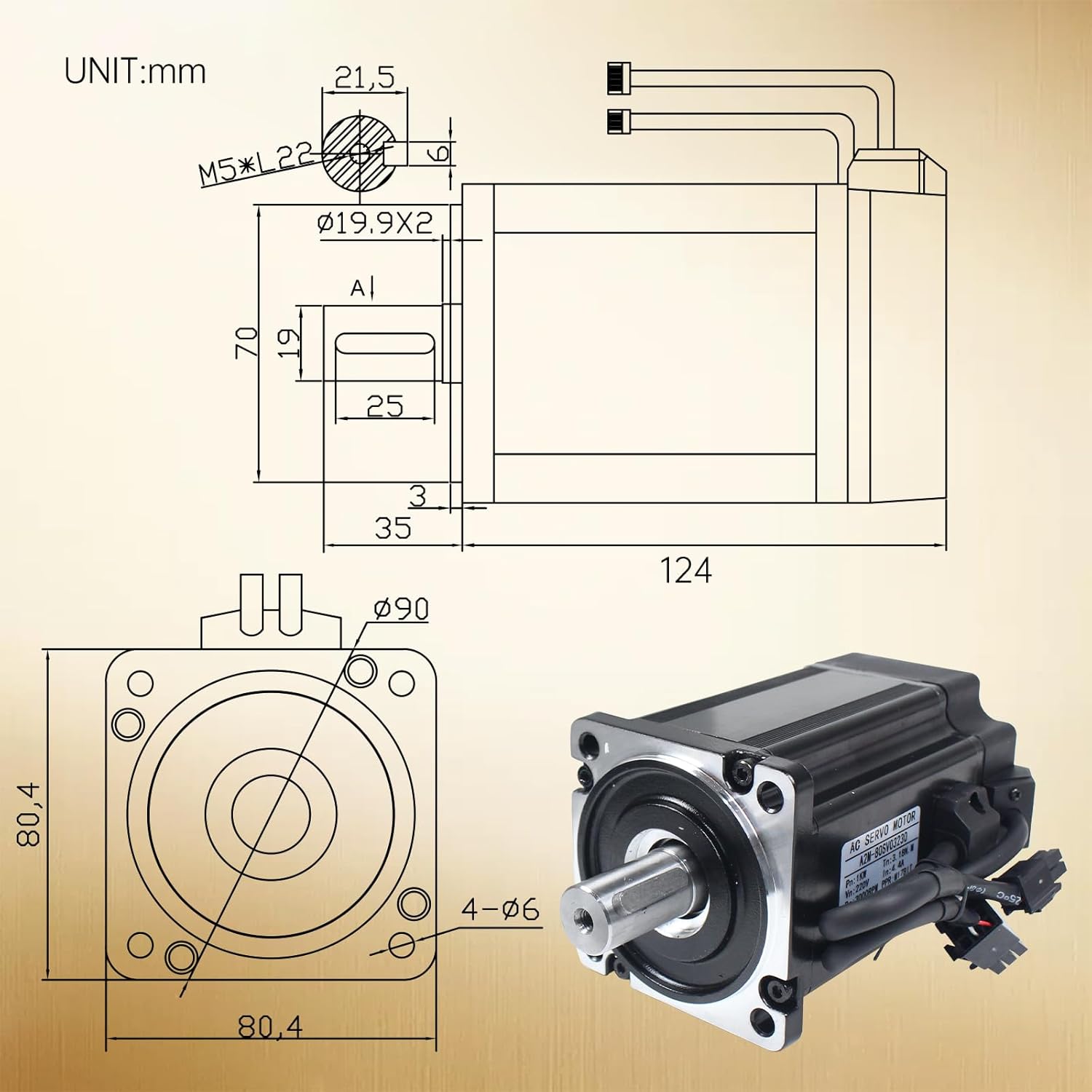

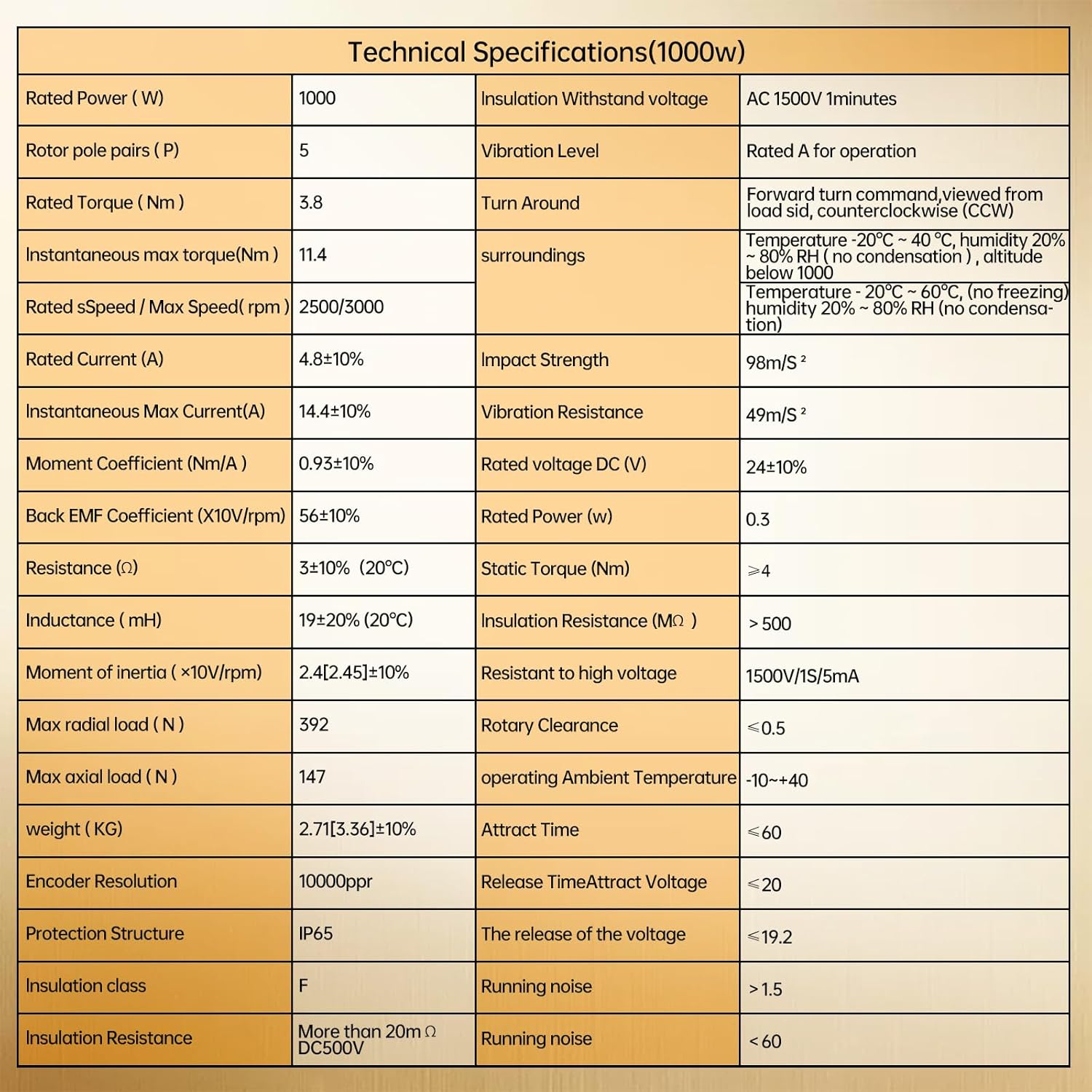

- Model: A2M-80SV03230

- Power: 1000W

- Rated power supply: 220V

- With brake: No

- Number of poles: 5

- Rated torque: 3.8 N.m

- Instantaneous max torque: 11.4 N.m

- Rated speed: 2500rpm/min

- Max speed: 3000rpm/min

- Rated current: 1.8A±10%

- Instantaneous max current: 14.4±10%

- Moment coefficient ( Nm/A ): 0.93±10%

- Back EMF Coefficient ( X10V/rpm ):56±10%

- Resistant( Ω ): : 3±10% ( 20℃ )

- Inductance: 19±20% mH ( 20℃ )

- Moment of inertia( X10V/rpm ): 2.4±10%

- Max radial load: 392

- Max axial load: 147

- Ender resolution: 10000ppr

- Protection structure: IP65

- Insulation class: F

- Insulation Resistance: More than 20mΩ DC500V

- Insulation withstande voltage: AC 1500V 1 minutes

- Bibration level: Rated A for operation

- Turn around: F0rward turn command view from load sid,counterclockwise ( CCW )

- Surroundings: Temperature-20℃-40℃, humidity 20%-80% RH ( no condensation ), altitude below 1000; Temperature-20℃-60℃,( no freezing ), humidity 20%-80% RH ( no condensation ).

- Inpact Strength: 98m/S²

- Vibration resistance: 49m/S²

- Rated voltage DC ( V ): 24±10%

- Rated power: 0.3

- Static torque: ≥ 4

- Insulation resistance: >500

- Resistance to high voltage: 1500V/1S/5mA

- Rotary clearance: ≤ 0.5

- Operating ambient temperature: -10 - +40

- Attract Time: ≤ 60

- Release Timeattract voltage: ≤ 20

- The release of the voltage: ≤19.2

- Running noise: >1.5

- Running noise: <60

- Mode selection key:Mode switching and return to the parent directory.

- Number increase key: Increase the number, and long press will have repeated effect.

- Number reduction key: Decrease the number, and long press has a repeating effect.

- Shift key: Cursor shift.

- OK key: Determine setting and End parameter setting.

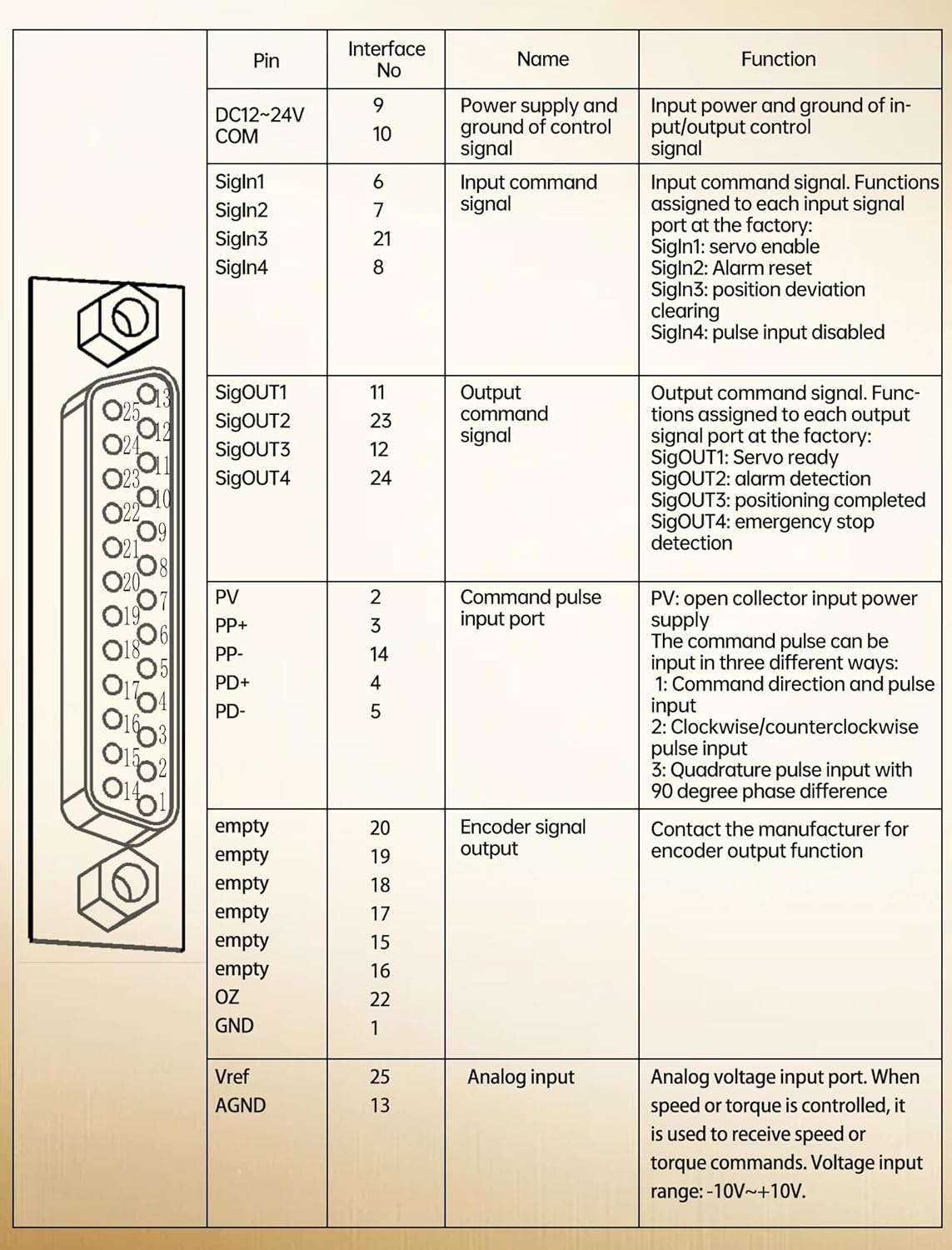

NO.9 (DC12-24V), NO.10(COM) :

- Power supply and gound of inout/output control singal.

NO.6 ( sigin1: servo cable ), NO.7 ( sigin2: alarm reset ), NO.8 ( sigin3: position deviation clearing ), NO.9 ( sigin4: pulse input disable ) :

- Input command signal. Functions assigned to each input signal port at the factory.

NO.2 ( sigout1: PV,open collector input power supply ), NO.3 ( sigout2: PP+ ), NO.14 ( sigout3: PP- ), NO.4 ( sigout4: PD+ ), NO.5 ( sigout4: PD- ) :

- The command pulse can beinput in three different ways:

- Command direction and pulse input

- Clockwise/counterclockwise pulse input

- Quadrature pulse input with 90 degree phase difference.

NO.20 ( empty ), NO.19 ( empty ), NO.18 ( empty ), NO.17 ( empty ), NO.15 ( empty ), NO.16 ( empty ), NO.22 ( OZ ), NO.1 ( GND ) :

- Contact the manufacturer for encoder output function.

NO.25 ( verf ), NO.13 ( AGND ) :

- Analog voltage input port. When speed or torque is controlled, it is used to receive speed or torque commands. Voltage input range: -10V~+10V.

220V AC SERVO MOTOR KIT 1000W WITHOUT BRAKE

Package Include

Wiring diagram of S2-SVD servo driver

Servo Motor Parameters:

Display Screen

DEFINITION OF CONTROL PORT CN2 PIN ( Interface No-Pin-Name-Fuctiom)

-

Customer ReviewsNo comments